The first item on yesterday's list was installing the fighting butt and reel seat ring. Putting this on before the reel seat makes it easier to install the reel seat later without it tending to slip off the end of the rod.

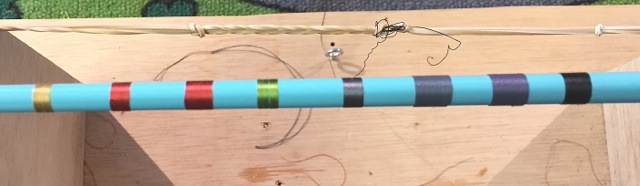

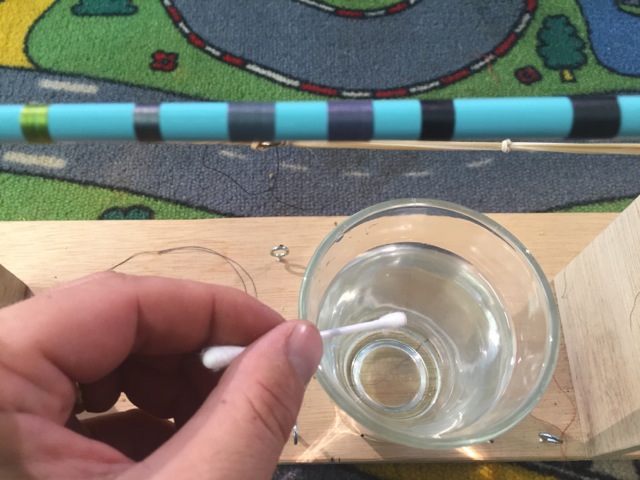

While that was setting, I went through the process of selecting the thread to use. I had ordered black silk as part of the build kit, but I am not all that convinced that silk would be strong enough on a 12wt rod being constructed to tackle Giant Trevally and perhaps sailfish. Nylon seemed a better option, but I was keen to line them up anyway, just in case one of the colours I already had was spectacular on the rod.

I must admit to being quite partial to the green silk (fourth from the left).

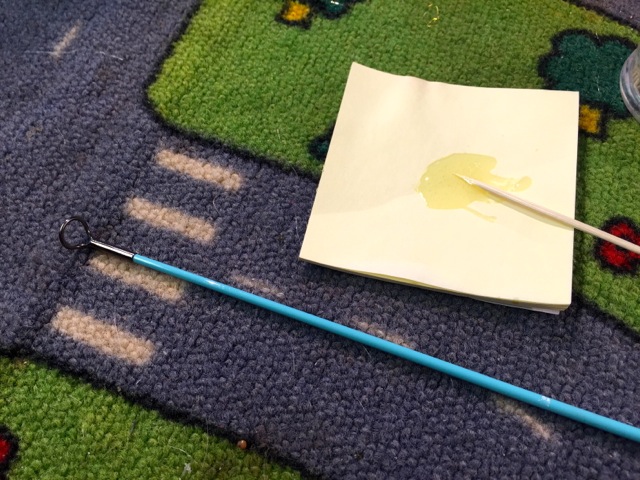

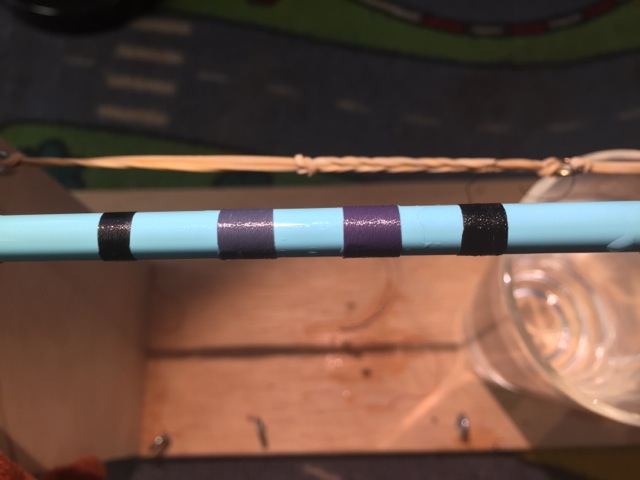

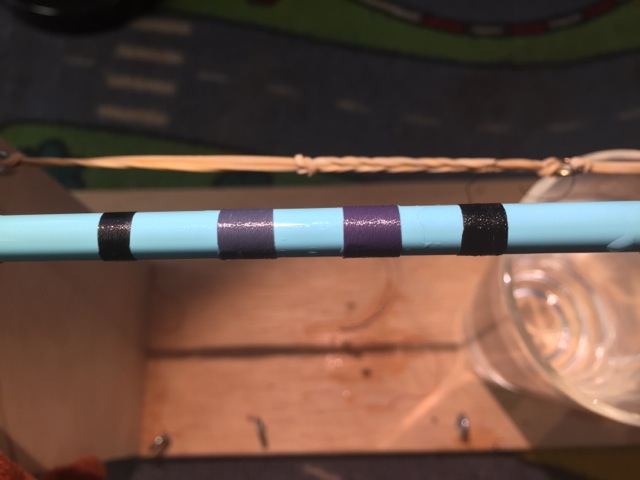

I wet the threads with water to see how they will look with epoxy on them. The green still looked pretty good, but I also liked the darker grey nylon (second from the right). (I'm showing the silk ones here for the benefit of others. By this time, I had decided the nylon options were the only ones for the rod.)

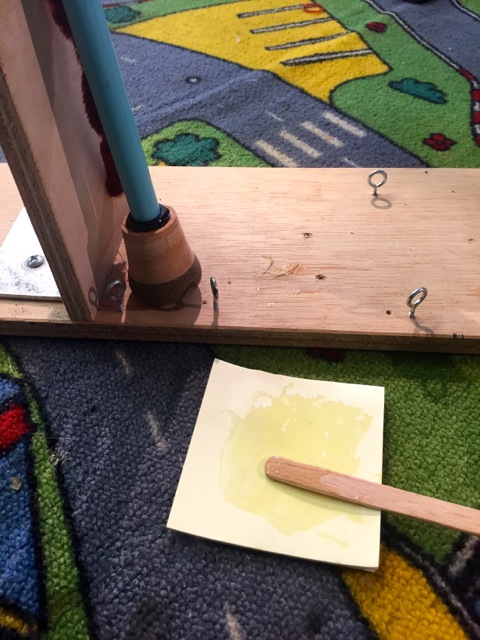

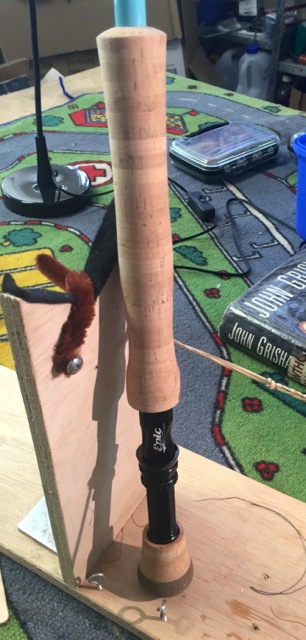

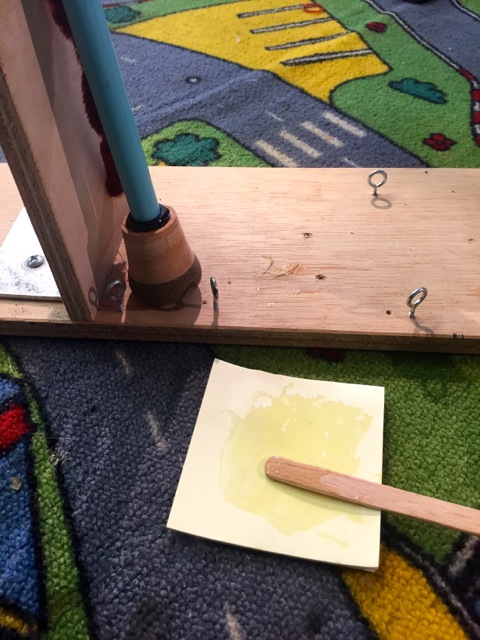

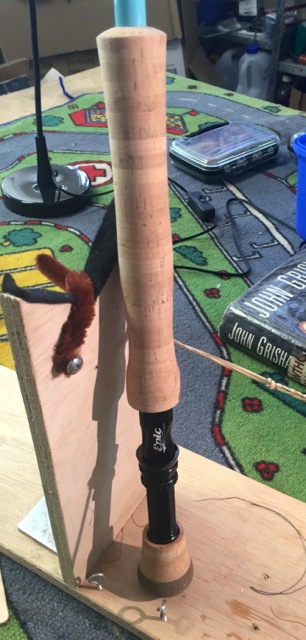

With the thread decided, I cut off the samples and began the task of installing the grip and reel seat. No preparation was required for the cork and only minimal arbors were required for the seat. (I also put tape around the thread of the reel seat to keep stray epoxy away during the installation. That is removed after everything is pushed into place and before the epoxy sets.)

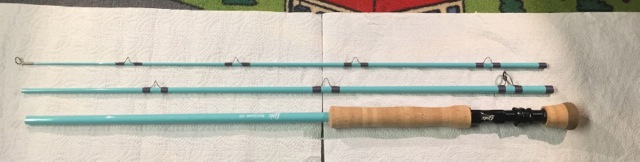

The butt section while the epoxy sets.

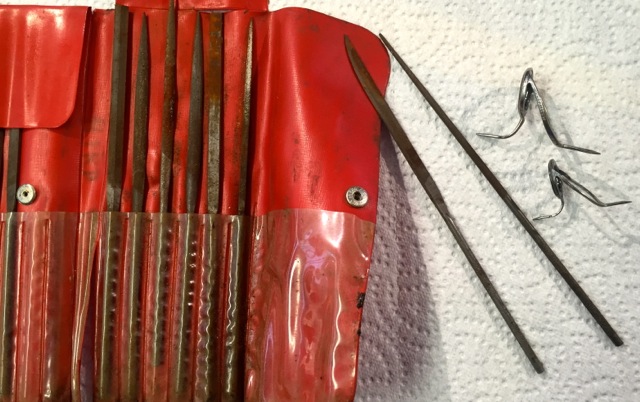

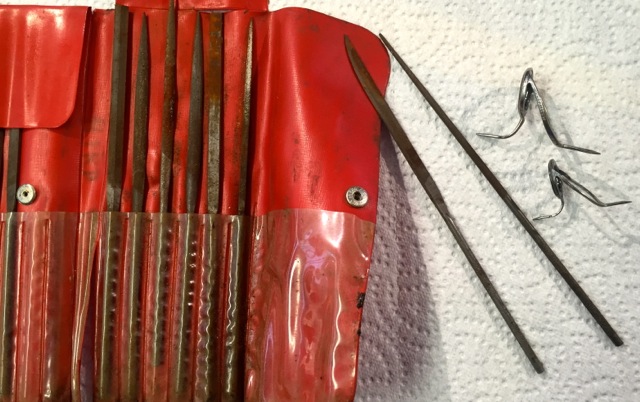

Regardless of what they may say at Epic or in the catalogs, I usually need to sharpen the feet of the guides to prepare for wrapping. If they aren't sharp, the thread tends to fall off instead of ramping up nicely. A few minutes spent sharpening them and removing burrs from the underside saves a lot of frustration later in the build. (These files were bought for me by my mother when I was 14 years old. She was hoping my obsession with gem cutting would extend into jewellery making. I use these jewellers' files for this work only and never did take up making jewellery ...

)

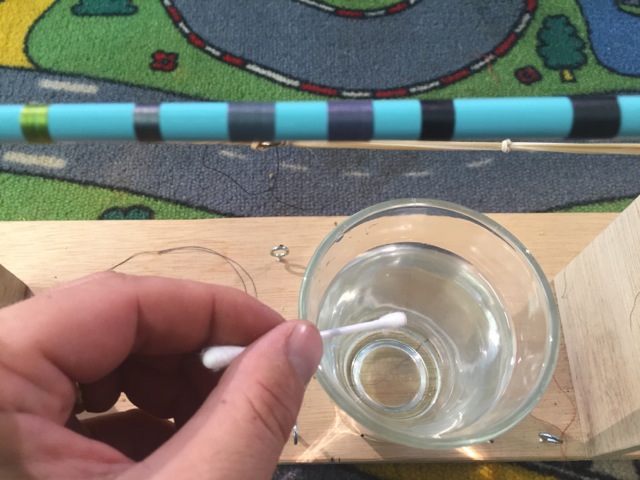

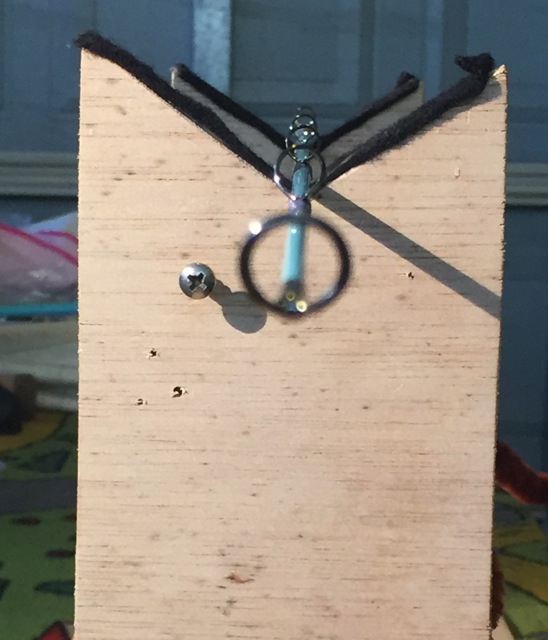

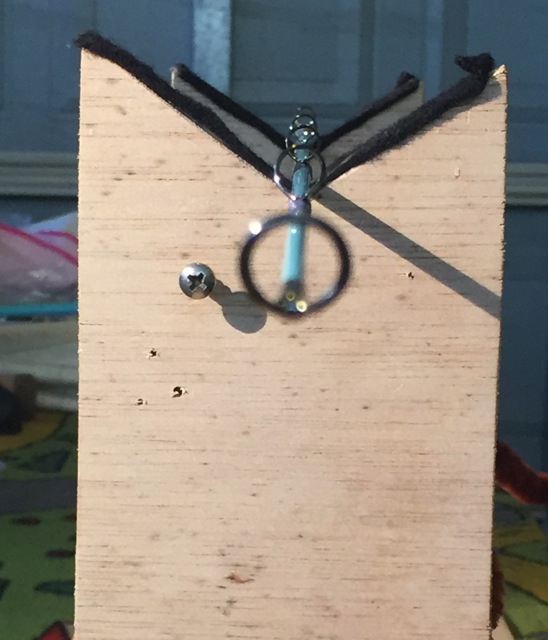

Now it was time to begin wrapping the guides. I keep the tension in the guide wraps with some rubber bands and a brass ring, plus a book (I find John Grisham's "The Client" in hard back just right.

) I run the thread through a series of eye-screws in various locations on my stand to allow a perpendicular run final to all parts of the blank. (You'll see this on the video I'm also putting together of this build.)

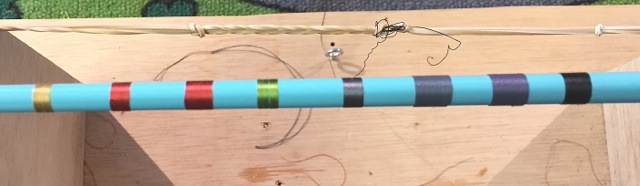

The tip section completed ...

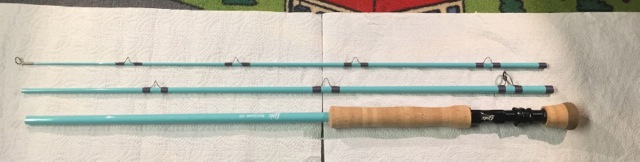

... and all work completed so far:

Only two stripping guides left to install and a little bit of aesthetic wrapping near the top of the handle. I may get them done today, but I'm keen to go fishing and it's going to be very hot in the afternoon (40 C tipped for the day), so I may end up collapsed on the couch with a beer instead.

Cheers,

Graeme